JOURNEY OF CREATING PURITY IN COTTON...

The customized experience for ever-growing demands. Economic yet practical experiences in benchmarked level of contamination removal.

JOURNEY OF CREATING PURITY IN COTTON...

The customized experience for ever-growing demands Economic yet practical experiences in benchmarked level of contamination removal

In the present scenario, spinners face multiple challenges with respect to the presence of contamination in the cotton bale. This is because of,

- High Contamination Variability: Cotton bales show lot-to-lot inconsistency with high volumes of contaminants, challenging quality control.

- Single contamination sorters achieve only 60–70% efficiency at the production of around 750kgs per hour, allowing significant contamination to pass through.

And has a consequential effects on operational impact,

- Higher contamination leads more FD & PP cuts in autoconers, reducing its efficiency.

- Higher incidences of FD & PP faults in yarn and fabric, lead to huge rejections

At Nestling, we are committed to transforming this challenge into a unique opportunity by offering a complete, integrated and still economic solution for the contamination challenges - setting a new benchmark in the process of contamination management.

Nature & Volume of contaminants

Photo indicates nature of contaminants

Our study reveals, Contamination in cotton bales varies widely, from 3 to over 45plus numbers per bale, differing by lot. As cotton moves through the Blow-room, contaminants break into smaller fragments, increasing the load on the Contamination Sorters, which is placed after the final beater. One Contamination sorter placed in a Blow-room line do perform at an average cleaning efficiency of 60 to 70 % (at a higher production in Blow room) and high contamination volumes lead to more particles to escape, affecting yarn and fabric quality.

Photo indicates nature of contaminants

The opportunities at NESTLING

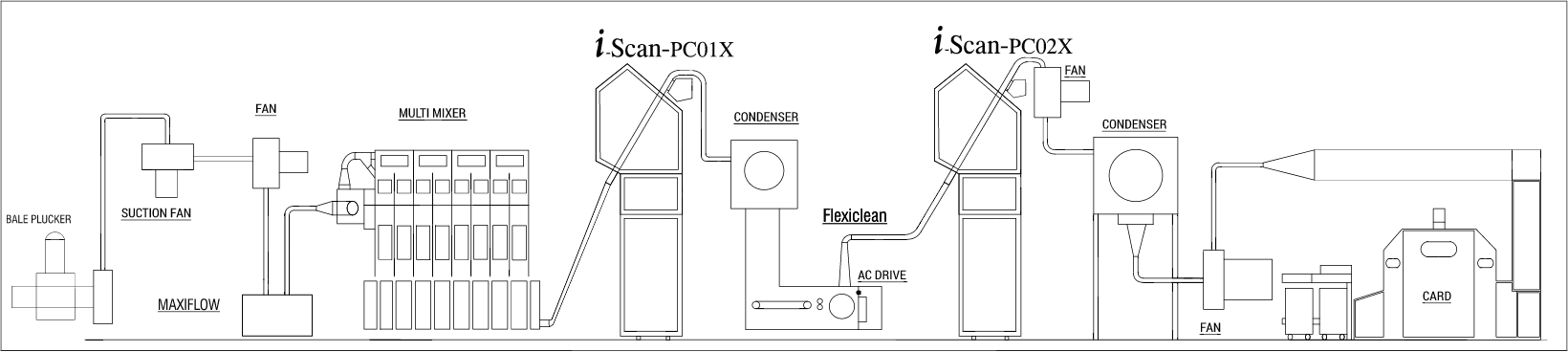

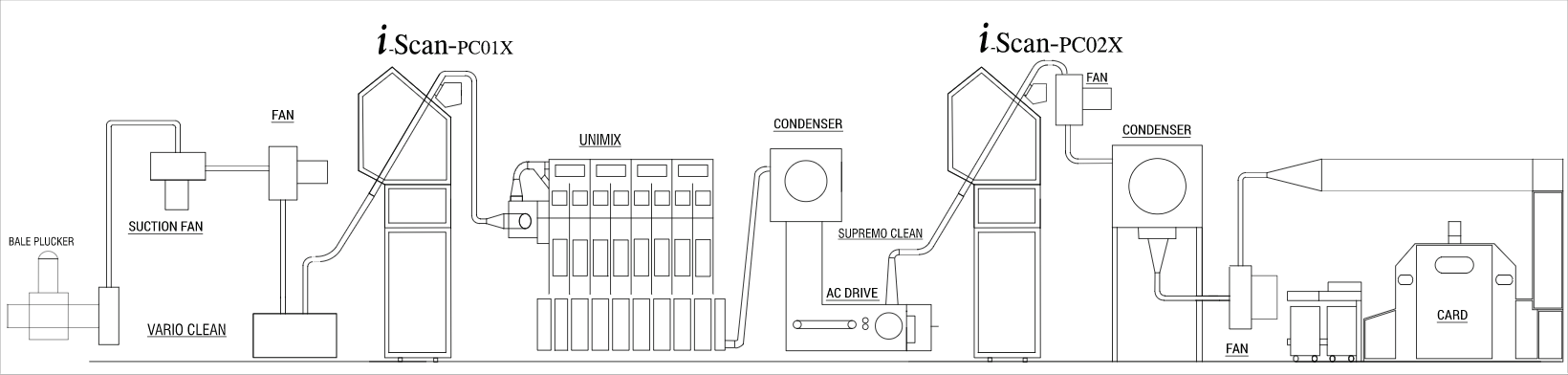

To address this critical issue, Nestling has launched NEST

Case studies of Creating a Healthy Customer Experiences

i) Three installations at Coimbatore – TN.

ii) one installation @ Tanuku - AP

Dual

Created Experiences

- Achieving benchmarked level of cleaning efficiency (Above 80 to 90% *)

- Branding and marketing pure cotton yarn at a premium cost

- Suppling to premium customers in the niche market

Committed Experience, High degree of ROI with

| Spindle Capacity | 50,000 |

| Count spun | 30s Combed Hosiery |

| Production / Spindle / Shift | 220 grams |

| Production / Spindle / Day | 660 grams |

| Total Production / Day | 33 tons |

| Total Production / Year & 360 days | 11,880 tons |

| When the “Contamination controlled Branded Yarn” sold at a premium of INR.1.0 / Kg, then Benefits / Year | Rs.1,18,80,000 |

| ROI | Around 7 to 8 months |

| When the “Contamination controlled Branded Yarn” sold at a premium of INR.0.50 Paise / Kg, then Benefits / Year | Rs.59,00,000 |

| ROI | Around 15 to 16 months |

FUTURE PLAN OF ACTION @ Nestling

- Creating an awareness about the importance of practices and process of contamination management.

- Empowering the more customers to becoming a market leader in selling “Contamination Controlled Yarn”.

- To build the solutions for effortless Contamination management process for the smarter future.

To be a part of the “Purity in cotton” movement, Please contact Customer Experience Team at 8925900951, or E-Mail: [email protected], [email protected], [email protected] (or) visit www.nestlingtech.com

Back to All Blogs

Back to All Blogs