NEST SOLUTIONS @ THREADS

Creating dignity in threads

i-Spin has been evolved to work and grow with dignity in threads. It is the commitment of "NEST `i-Spin"' to grow with self-respect, goodness and majesty in threads, that ensures elegance in fabric

DIGNITY IN THREAD IS

ENSURED BY LIVING UP

TO THE GUIDING

PRINCIPLES

- Understanding the meaning of "Dignity" in threads

- Organising to create "Dignity" in threads

- Creating "Dignity" in threads.

- Evaluating the creation of "Dignity" in threads.

- Improvement of "Dignity" in threads.

- Learning to create values in continuous basis.

UNDERSTANDING THE MEANING OF "DIGNITY" IN THREADS.

UNDERSTANDING REAL-TIME MONITORING OF SPINDLE PERFORMANCE

-

TO REDUCE DEPENDENCY OF

SKILLED MAN POWER TOWARDS ACHIEVING THE EXCELLENCE IN SPINNING PROCESS.

-

ENABLING TO IMPROVE

OPERATOR'S EFFICIENCY BY MINIMIZING NON-PRODUCTIVE MOVEMENTS AND PROVIDING A COMFORT ZONE.

-

UNDERSTANDING THE NEED OF

COMPREHENSIVE REPORTING, ACCESSIBLE ANYWHERE ANY TIME.

UNDERSTANDING THE NEED FOR ROUND THE CLOCK MONITORING OF

RING SPINNING

-

PRODUCTION

-

POWER

-

RH AND DRY BULB

-

INDIVIDUAL SPINDLE STATUS - END BREAK, IDLE,

-

ROGUE AND SLIP SPINDLES

PREPARATORY

-

PRODUCTION

-

POWER MONITORING

-

RH AND DRY BULB

-

STOPPAGE DETECTION

-

UTILITIES POWER MONITORING

ORGANISING TO CREATE "DIGNITY" IN THREADS

Resources Organised

FIRST OF ITS KIND TO IMPLEMENT CLOUD BASED SYSTEM, WHICH FACILITATES HUGE DATA STORAGE, ARTIFICIAL INTELLIGENCE -BASED ANALYSIS AND ACCESS ANY TIME ANYWERE IN THE WORLD.

IOT ENABLED WI-FI TECHNOLOGY ASSURES 100% DATA SAFETY AND SECURITY.

PANORAMIC SPIN VIEW ENABLES PROGNOSIS OF DEFECTIVE SPINDLES AT REAL TIME.

ALL CRITICAL DATA IS DISPLAYED IN A SINGLE SCREEN.

HIGHLY FUNCTIONAL TOUCH SCREEN DISPLAY AT EACH MACHINE TO ANALYZE MACHINE DATA.

HIGHLY INFORMATIVE DASHBOARD, TV SCREEN, MOBILE APP.

MULTI COLOR INDICATIONS FOR EACH SPINDLE.

VIDEO REPORTS OF PANORAMIC VIEW

UNIQUE ADD-ONS FOR FURTHER VALUE CREATIONS TO MEET CUSTOMERS SPECIFIC REQUIREMENTS.

CREATING "DIGNITY" IN THREADS

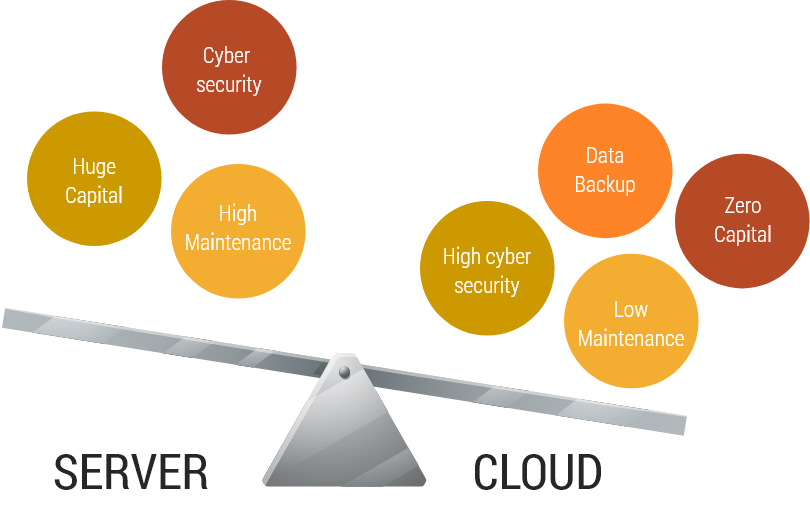

CLOUD BASED SYSTEM

-

HUGE DATA STORAGE FACILITIES

-

AI BASED ANALYSIS

-

AWS CLOUD SYSTEM

-

THREE TIER DATA SAFETY AND SECURITY PROVIDES HIGH DEGREE OF REDUNDANCY

-

99.99% UPTIME

-

CUSTOMER CAN OPT FOR CLOUD OR SERVER OR BOTH FOR DATA MANAGEMENT

IOT ENABLED WI-FI TECHNOLOGY

-

ACCESSIBLE FROM ANYWHERE AT ANYTIME

-

ENABLING TO CONTROL THE MACHINE TO OPTIMISE THE PERFORMANCE FROM REMOTE

-

SOFTWARE UPDATES POSSIBLE FROM REMOTE

-

100% DATA SAFETY AND SECURED

SIGNATURE VALUE CREATING FUNCTIONALITIES

REVOLUTIONISED PANORAMIC SPINDLE VIEW

50,000 SPINDLES PANORAMIC VIEW IN ONE SCREEN IN REAL TIME

END BREAKS

ROGUE SPINDLES.

SLIP SPINDLES.

IDLE SPINDLES (MACHINE AND OPERATOR IDLE SPINDLES SHOWN SEPARATELY)

DOFF INDICATION.

STOP INDICATION WITH TIMER.

DOFF STATUS INDICATION.

TRAVELLER CHANGE SCHEDULE.

MAINTENANCE SCHEDULE.

MANGO TUBE MAINTENANCE (FOR COMPACT)

DATA LOSS INDICATION.

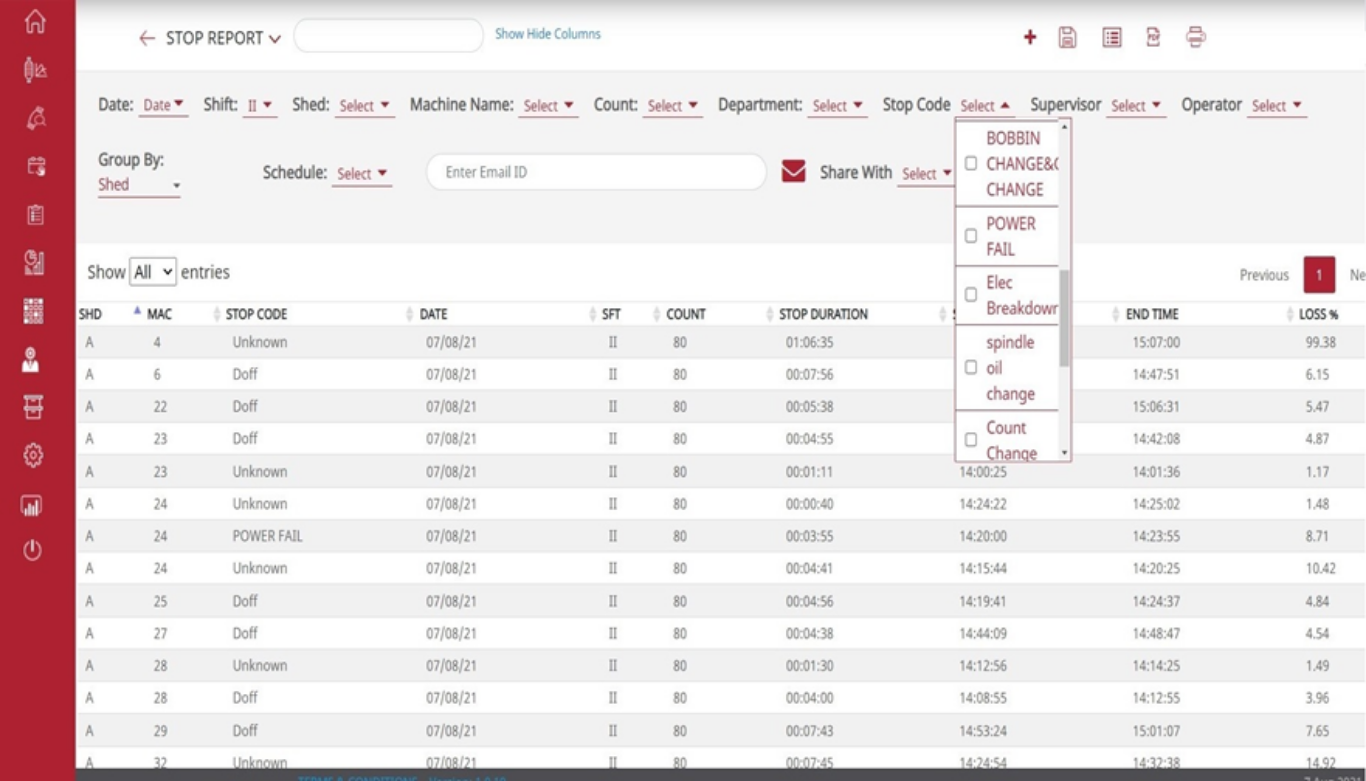

STOP REPORT

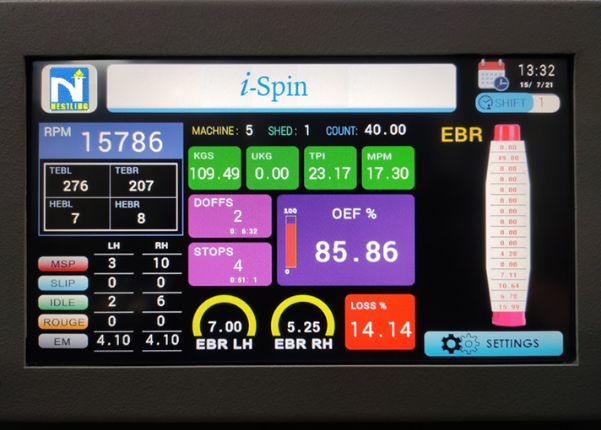

MACHINE TERMINAL TOUCH SCREEN DISPLAY

ALL CRITICAL DATA ARE DISPLAYED IN A SINGLE SCREEN

EFFICIENCY

SPINDLE SPEED

END BREAKS EBL / EBR

END MENDING TIME

TOTAL BREAKS

HANDOVER BREAKS

TPI

DELIVERY RATE M/MIN

PRODUCTION IN KG

ROGUE SPINDLES

SLIP SPINDLES

STOP DETAILS

UKG

TAPE CUTS

COP STAGE WISE BREAKAGES

MULTI SHIFT DATA ARE DISPLAYED

ACTS AS MACHINE ENTRY TERMINAL TO ENTER STOP DETAILS AND MACHINE PARAMETERS

3 MONTHS DATA CAN BE STORED AT THE MACHINE TERMINAL DISPLAY ITSELF

IOT ENABLED WI-FI TECHNOLOGY ASSURES 100% DATA SAFETY AND SECURITY

NO INTERMEDIATE MANUFACTURER DEPENDABLE DEVICES USED FOR COMMUNICATION

CUSTOMER CAN OPT FOR CLOUD OR SERVER OR BOTH FOR DATA MANAGEMENT.

15 KG PER MACHINE LESSER WEIGHT RAILS THAN OTHER SUPPLIERS – HELPS IN ENERGY SAVING

VIDEO REPORTS OF PANORAMIC SPINDLE VIEW

COMPREHENSIVE DASHBOARD REPORTS

THE DETAILS OF EFFICIENCY WITH EBR, PRODUCTION LOSSES, END MENDING DETAILS, STOP DETAILS, REAL TIME OPERATOR EFFICIENCY, ROLLS OFF, DAY’S PRODUCTION AND UNAUTHORIZED DOFF TIME ENABLED WITH DATA FILTER

CHOICE OF CLOUD OR SERVER

SERVER COST, OPERATING SYSTEM LICENSES, ANTIVIRUS LICENCES COST ARE HUGE

LOW MAINTENANCE COST AS IT’S SHARED BETWEEN MULTIPLE CUSTOMERS

I-SPIN IS HOSTED BY WELL RENOWNED AMAZON CLOUD SERVICE,

THE PREMIUM PLATFORM AVAILABLE IN THE MARKET

24X7 AND DIFFERENT GEOGRAPHICAL LOCATION DATA BACKUP AND 99.99% UPTIME GUARANTEED

CLOUD CAN HOLD LARGE DATA.

MULTI COLOR INDICATIONS FOR EACH SPINDLE

RED COLOR TO INDICATE BREAKS

GREEN COLOR TO INDICATE IDLE BREAKS

RED FLASHING TO INDICATE ROGUE SPINDLES

GREEN FLASHING TO INDICATE SLIP SPINDLES

DEFECTIVE COPS IDENTIFICATION

THE ROGUE AND SLIP SPINDLES ARE IDENTIFIED DURING DOFFING FOR EASY

SEGREGATION AND REMOVAL

EVALUATING THE CREATION OF “DIGNITY” IN THREADS

A MEASUREMENT OF REAL TIME SPINDLE STATUS UPDATE FOR VALUE CREATING DECISION AND WASTAGE ANALYSIS

IMPROVEMENT OF “DIGNITY” IN THREADS

UNIQUE ADD-ONS FOR IMPROVEMENTS IN VALUE CREATIONS TO MEET THE CUSTOMERS SPECIFIC REQUIREMENTS

- PNEUMAFIL CONTROL – ENERGY SAVING

- AIR MONITORING FOR MACHINES & COMPRESSORS

- RELATIVE HUMIDITY RH % & DRY BULB

- BOBBIN RUNOUT DETECTION AND INDICATION (BRD)

- ROVING DETECTION FOR SIRO YARNS

- ROVING STOP MOTION (RSM)

- FILAMENT STOP MOTION (FSM)

- AUTOMATIC BREAKAGE CONTROL (ABC)

- AUTOMATIC ILLUMINATION CONTROL (AIC)

- PREPARATORY MONITORING SYSTEM (PMS)

- POWER BI BASED BIG DATA ANALYSIS *

- OPERATOR SURVEILLANCE SYSTEM (OSS)

- MOTOR TEMPERATURE MONITORING SYSTEM

- VIBRATION MONITORING SYSTEM

LEARNING TO CREATE VALUES IN

CONTINUOUS BASIS

CREATED VALUES

27% improvement in end mending time (Operator efficiency)

20% increase in productivity

Waste reduction more than 50%

5% lighter rail (15Kgs lesser weight for 1200 spindles)

30% Energy saving by optimizing shop floor lighting

Elimination of Xomponent Damages with RSM

Reduction in second quality yarn sales by 33%

Autowinder improvement in performance 2%

Payback period less than 9 months

Product Enquiry

Product Enquiry